Servochron Single/Dual Servo Timer you build yourself!

Table of contents:

Please click a links below to jump to a section of the documentation.Introduction:

The ServoChron™ is a low cost time delayed servo controller designed for use as a parachute deployment or staging actuator mechanism for Water Rockets, or Water Rocket Propelled Vehicles. There are other potential applications for the ServoChron™ , but this document primarily focuses on the Water Rocket parachute deploy application. The ServoChron™ was created specifically to make servo controlled recovery and staging mechanisms easy to build, and affordable for everyone.The core of the ServoChron™ is the Texas Instruments MSP430 LaunchPad. This board is an inexpensive microcontroller hobbyist experimenting platform that you program application firmware into with a USB cable. The FREE ServoChron™ application firmware file created by U.S. Water Rockets turns the MSP430 LaunchPad into a user programmable servo deployment system timer/controller.

The custom firmware acts as a timer and servo motor driver which monitors a trigger switch and individually actuates up to two separate servo motors when a previously configured delay time for each has elapsed following the trigger condition. The trigger switch is most often used to detect the launch of the Water Rocket and the timer delay is set to the predicted time to reach apogee.

In a single servo application, the servo motor will then activate, and release a main parachute for a controlled descent.

In a dual servo application, one servomotor usually is used to deploy a small drogue parachute at apogee, and the second servo motor is used to deploy a larger main parachute some time later, when the rocket is closer to the ground. The dual servo setup can be used to prevent the rocket from drifting away while descending.

Another application commonly requiring dual servos is to deploy two independent parachute systems at apogee for redundancy. There are limitless applications to explore.

The ServoChron™ was designed and tested by the renowned U.S. Water Rockets, which have been featured on internationally broadcast programs like MythBusters. ServoChron™ is the result of many years of experience in setting Water Rocket World Records as well as recreational and scientific Water Rocket experiments.

- Servo Deploy control for up to 2 servos

- Independent Launch Trigger timer and/or Apogee Detect Trigger operation

- Built on the low-cost MSP430 LaunchPad Platform

- Operates on 3.7V-6V DC. You may use various power sources including a single lightweight Lithium Polymer rechargeable cell

- User defined servo positions for up to two individual servos

- User programmable delay for each servo from 0.000 to 30.000 seconds in 1 millisecond increments

- USB Firmware update (with included cable! No special programming hardware to buy!)

- Edge sensitive trigger inputs with automatic polarity detect

- Dual trigger inputs capable of sensing contact open or close events shorter than 10 nanoseconds

- Optional input for external apogee detect or radio control trigger

- Innovative 2-button operator interface with easy to remember setup

- 3 Status LEDs

- UART (Serial) diagnostics mode

- Dimensions: 2.0 x 2.6 inches (50.80 x 66.04 mm)

- Weight : 0.635 oz (18 grams)

- Includes testing and arming operational modes

- Fully RoHS compliant. Contains legal levels of lead and hazardous materials

Purchasing information:

You will need to purchase your own MSP430 LaunchPad board, servos, and battery, and put the device together yourself with the simple instructions provided. See the assembly section for full parts list and prices.[Back to Table of Contents]

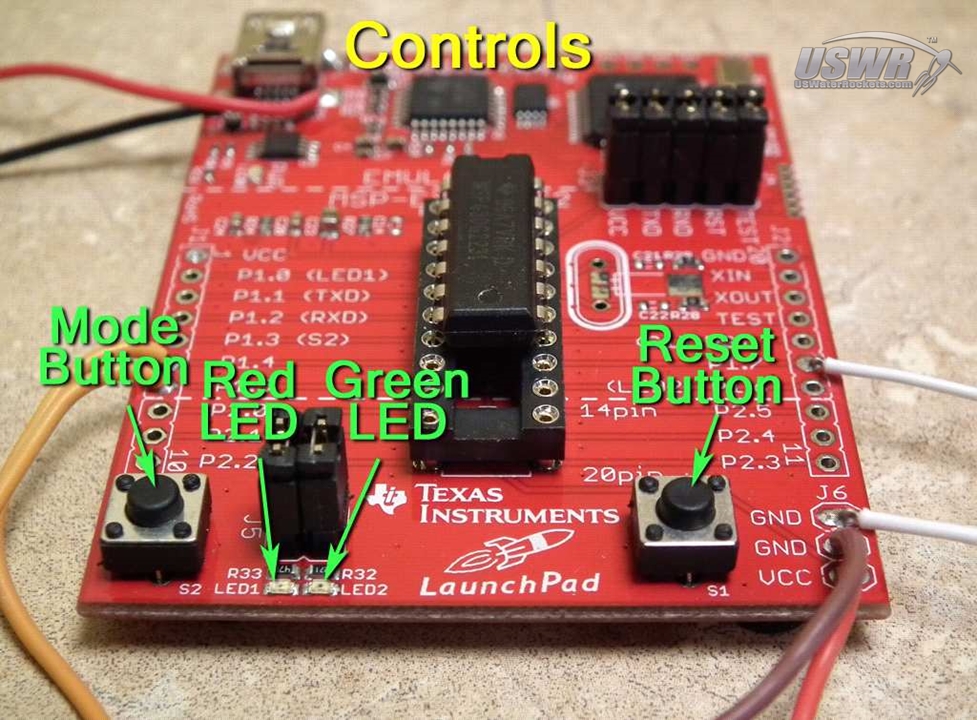

Operation & Controls

All configuring of the user parameters is done using the custom designed Operator Interface of the ServoChron™. The interface controls consist of two pushbuttons and 3 LEDs. The pushbuttons are defined as follows:- S1 = Reset (Right) – This button will reset the ServoChron™ and is used to set up the delay timers.

- S2 = Mode (Left) – This button is used to change modes and set up all configuration parameters.

- Power - This Green LED near the USB connector LED illuminates whenever power is applied to the ServoChron™

- Red = Servo 'A" Status indicator - This LED is used to configure Servo 'A'

- Green = Servo 'B' Status indicator - This LED is used to configure Servo 'B'

Configuration Modes:

The ServoChron™ has two configuration modes which must be set up prior to first use after programming the firmware. Once configured, the settings are stored in nonvolatile memory and will be remembered each time you power up or reset the ServoChron™, or until you choose to modify the settings. The operator interface was designed to maximize ease of use, and eliminate the need for any special tools, cables, cheat-sheets, software, or even a computer.Note: If you are using a single servo, you should still program some sensible values for the unused servo settings.

The ServoChron™ configuration modes are:

Servo Positioning Definition Mode: This mode is used to define where the servomotor “home” and “deployed” positions are. Follow these steps to configure the two positions:

- Hold down the Mode button while connecting power to the ServoChron™. The Red LED will light steadily to indicate the Servo ‘A’ home position is being set.

- Tap the Mode button to change the “home” position in 30 degree increments until you reach the desired angle.

- Press and Hold the Mode button for longer than 1 second to save the “home” position. The Red LED will now go dark, and Servo ‘A’ will move into the "deployed" position.

- Configure the “deployed” position the same way as described for the “home” position.

- The Green LED will low illuminate indicating that you are now configuring the “home” position of Servo ‘B’. The positions for Servo ‘B’ are configured the same was as they are for Servo ‘A’. Set both positions for Servo ‘B’ now.

- Press and hold the Mode Button in and tap the Reset Button.

- Continue to hold in the Mode button, and release it when the delay time for Servo ‘A’ has elapsed.

- Wait additional time and then tap the Mode button to set the Servo ‘B’ delay time when the desired delay has elapsed.

- Press and hold the Mode Button in and tap the Reset Button.

- Continue to hold in the Mode button, and release it when the delay time for Servo ‘A’ has elapsed.

- Wait additional time and then tap the Mode button to set the Servo ‘B’ delay time when the desired delay has elapsed.

Operation Modes:

Standby Operating Mode: This mode is entered by default at power up. When this mode is active, the servos will move to their "home" positions and The Red and Green LEDs will display a blinking pattern to remind you what the delay timer settings are. The pattern is one flash per second blink rate for the duration of each timer delay, followed by a two second pause with both LEDs on. This blinking pattern repeats forever. When this mode is activated, the state of the launch detect switch is read constantly and any change is detected. When a change is sensed, the triggered mode is activated.Note: short delay times will result in a very small period of the LED "Off" off between 2 second pauses. If you set it very short, you nay not be able to see the LED in the "Off" state.

Triggered Mode: When triggered mode is activated, the status LEDs will begin to rapidly blink as the timer delays are counting down. When each timer delay has elapsed, the associated servo will move to the Deployed Position and once both servos have been actuated, the ServoChron™ will go into Deployed Mode.

(Optional) Apogee Detect Mode: If used this mode will override the timer delay and go into deployed mode. When used in this way the Apogee Detect trigger can be connected to an apogee detect system and the timer deploy can still function as a backup. Leave the apogee detect trigger input disconnected if you are not using this mode.

Deployed mode: This is the final mode which is activated once the ServoChron™ has actuated the servo(s). In this mode, both LEDs will blink once every 4 seconds to indicate the deployed mode is active. Both servos will be held in the "deployed" position for 2 minutes and then the servo outputs will be deactivated to conserve battery power. You must press the Reset Button or cycle power to exit this mode.

Test/Arming Mode: This mode is available when the ServoChron™ is in Standby Operating Mode and the Mode Button is pressed and held in. When this condition is detected, the servos will be forced to move to their "deployed" positions. You can use this to test your deploy systems, or you can use this mode to arm your deploy mechanisms if you have designed them with a positive latch. When the Mode button is released, the ServoChron™ automatically goes back into to Standby Operating Mode.

[Back to Table of Contents]

Error Codes:

The Red LED indicates all error conditions by turning on steadily and briefly flashing OFF a number of times in a repeating cycle. The number of OFF flashes will reveal the error code.The possible error codes are:

- 2 Flashes = Time Configuration Error

- 3 Flashes = Servo Configuration Error

| Symptom: | Possible causes: | Corrective Action: |

| I get a Time Configuration Error | You have set one or both time delay for longer than 30 seconds | Reconfigure the delay times and be sure to set them both to values less than 30 seconds. |

| You are powering up for the first time after loading firmware. | ||

| I get a Servo Configuration Error. | You have set the “Home” and “Deployed” positions of one or more servos to the same location. | Reprogram the servo positions and be sure that each servo has different locations for each of the two positions. |

| You are powering up for the first time after loading firmware. |

ServoChron™ Theory of Operation:

In normal use, the ServoChron™ powers up and directs the servomotors to move to their "home" positions.- ServoChron™ monitors the trigger input for a state change. In a typical Water Rocket this could be an acceleration or vibration switch or a simple pushbutton held depressed by the launcher. When the Water Rocket is launched, the trigger condition is detected.

- ServoChron™ begins timing for the preconfigured interval calculated to approximate the time to apogee. When the Servo 'A' time interval has elapsed, the rocket would be at the apogee, and ServoChron™ directs the Servo 'A' to move to the "deployed" position. The mechanical motion of the servomotor is now used to release a parachute. This can be the main parachute, or a drogue parachute if you are using two servos. If you have dual servos configured and installed, when the Servo 'B' interval has elapsed, the rocket will have descended for a while, and ServoChron™ directs t Servo 'B' to move to the "deployed" position, releasing the larger main parachute.

- If you are using the Apogee Detect Trigger this input will override the timer for Servo 'A' and cause it to move into the deployed position. This allows the ServoChron™ to be used as a servo activator for external apogee detection circuits. Note: Servo 'B' will also move to the deployed position after the Apogee Detect Trigger is detected plus the difference between the Servo 'A' and Servo 'B' timer intervals has elapsed, so the main/drogue feature is preserved.

[Back to Table of Contents]

Assembly

-

Tools Required:

- Wire Cutter / Stripper

- Soldering Iron

- Solder

Parts List:

To assemble a complete ServoChron™ Single/Dual Deploy System, a number of components are needed. The design has been thoroughly tested using the components listed below. Where noted, you may be able to locate equivalent replacement components which could suit your specific application.- 1x MSP-EXP430G2 - MSP430 LaunchPad Value Line Development kit

- 1x MULTICOMP - R13-509A-05-BR - SWITCH, PUSHBUTTON, SPST, 3A, 250V (Or equivalent)

- 1x Turnigy 160mAh 1S 130C Lithium Polymer Cell (Or Equivalent)

- 12 inches of #22 Gauge Wire

- 1 or 2 HXT900 9g / 1.6kg / .12sec Micro Servos (Or equivalent)

- Mini Plug Extension for Micro Battery 10cm (5pcs/bag)

- JR-Type Servo Extension 10CM Servo Lead (JR) 32AWG Ultra-Light (10pcs/bag)

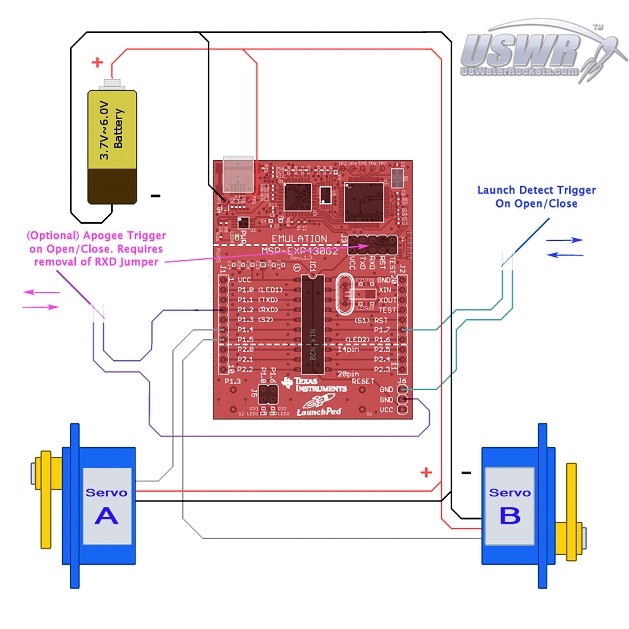

Wiring Diagram:

There are only 10 primary and 2 optional connections which must be made to the MSP430 LaunchPad Evaluation Kit Printed Circuit Board. These connections are illustrated in the diagram below. Note: If you are making a single servo version, you can leave off Servo B and the connections associated with it.

[Back to Table of Contents]

Programming Instructions

The core of the ServoChron™ Deploy System is the MSP430G2231 (Or MSP430G2553 on newer LaunchPad boards) microcontroller from Texas instruments. This microcontroller contains flash memory which must be programmed with the ServoChron™ firmware to create the deploy system. Texas Instruments has created a very low cost evaluation board which contains all the circuitry needed to program the MSP430G2231/MSP430G2553, which is used as the main board for the ServoChron™.Once you have made the connections requited in the Assembly Instructions to the MSP430 LaunchPad, the only step which remains is to download the firmware into the microcontroller. There are several ways to download the firmware, but this document references a FREE stand-alone application which can download the firmware file with a single mouse click.

Hardware Required:

- MSP430 LaunchPad Evaluation Kit.

- PC with Windows XP or later Operating System.

- Elprotronic FET-Pro430 Lite (from elprotronic.com).

- Download the ServoChron™ Firmware Project File http://www.uswaterrockets.com/shared/servochron/ServoChron_firmware.zip and extract it into a folder on your PC.

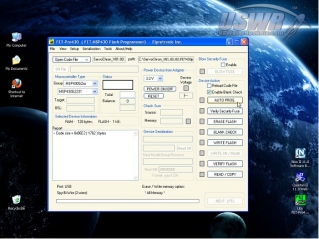

Programming Step 1: Download the Programming Software Tool:

Go to the website http://www.elprotronic.com/download.html and download the free program called "FET-Pro430 Lite". When the download has completed, read the installation instructions and follow the procedures for installing the software and the USB drivers included.Programming Step 2: Run the FET-Pro430 Lite Software:

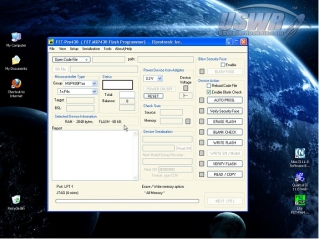

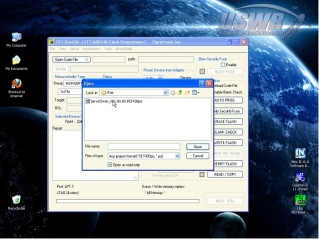

Find the programming tool icon on your desktop or in the program start menu of your PC and execute the application. Note: please make sure that you have followed all the USB driver installation instructions before running the application or connecting the USB cable to the MSP430 LaunchPad.Programming Step 3: Load the firmware project file into the programming application:

Go to the "File" menu of the FET-Pro430 Lite application and click on "Open Project". You will then be presented with a file open dialog with which you will navigate to the directory where the firmware project file is stored. You select the firmware you wish to load and click "Open". The project file will then load into the programming application.Programming Step 4: Program the Microcontroller:

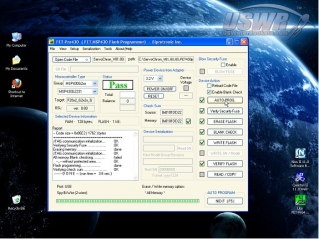

Disconnect any batteries from the ServoChron™ and connect a USB cable from your PC to the USB port.Warning: You must NEVER connect the battery and the USB cable at the same time.

You can damage your PC or the ServoChron™, or cause the battery to explode.

Once you have connected the USB cable you can press the "AUTO PROG." button to load the firmware file. The programming tool will report "PASS" when the operation is complete. Note: There are multiple versions of the MSP430 Launchpad on the market. This software will work on all of the currently available models but you may get a warning message when you program a newer model with this software. Confirm the message and continue the software download if this situation arises.

Programming Step 5: Finishing:

Close the programming software and disconnect the USB cable from your computer. You are now ready to use your ServoChron™. Before launching, you will need to configure the servo positions and time delay. Note: Please save these instructions and keep the programming software installed and up to date on your computer, because this tool will be used to program ServoChron™ Firmware Updates as well as future U.S. Water Rockets projects. [Back to Table of Contents]Diagnostics

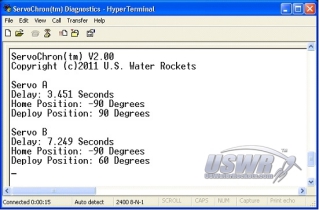

The ServoChron™ can optionally communicate directly with a personal computer using the MSP430 Application UART which is built into the MSP430 LaunchPad. This feature provides USB to RS-232 conversion hardware connected to the microcontroller which communicates using a secondary link over the USB debugger interface. With this mode, you can get a readout of all the current settings as well as diagnostic error codes which may help in troubleshooting.Software Required:

To enable the UART Debug Interface, you may need to install one or two software packages on your Windows based PC:

Serial Terminal Software Application: Most installations of Windows prior to Vista will include a terminal application as part of the basic windows package. This is usually called "Hyterterminal". If you do not already have a terminal program on your PC, there are many open source terminal programs available. We recommend an application called Tera Term, which you can download from here: http://ttssh2.sourceforge.jp

MSP430 Application UART Driver: This software is needed to enable the USB to Serial Port Converter hardware built into the MSP430.

To install the MSP430 Application UART:

- Download the driver software from the following link: http://www.uswaterrockets.com/shared/MSP430_LaunchPad_Drivers.zip and extract it into a folder on your PC

- Plug in your MSP430 LaunchPad to a USB port on your PC.

- Open "Control Panel>System>Hardware>Device Manager" and find the entry for "MSP430 Application UART" in either "Ports" or "USB Controllers" (the exact location varies depending on windows version)

- Click on "MSP430 Application UART" and under "Drivers" there will be an "Update Driver" option. Click this button and select the option to load a driver from a specific location.

- Select the location where you saved the extracted drivers from step 1, and click OK. The drivers will now install.

- A port name/number will be assigned to the MSP430 Application UART and will be displayed in the Device Manager. It would typically be called COMx (where 'x' is a number). Write this value down for later reference.

To use the Diagnostic UART you must open your Terminal Program and set the communications port to the "COMx" value assigned to the MSP430 Application UART (from Step 6 above). When you select that port as the terminal communications port, you will also neet to set the parameters that the ServoChron™ firmware requires. To do this, find the dialog box where you configure the serial port properties and configure the settings. You will need to open the dialog and configure the following settings (see Figure 10) for your specific COM port number: Once you have the terminal configured, you will see the diagnostic messages shown above (See Figure 9) whenever you press the Reset Button on your ServoChron™. You may use this mode to check your settings or to verify they are correct before a launch. You may also look for diagnostic messages which will display if an error is detected. Notes:

Windows does not have very robust support for RS-232 over USB and so you can easily cause the driver to freeze up by unplugging the USB port while connected to the terminal. To avoid locking up the port, please be sure to close the terminal completely before unplugging the USB cable. You may also have to re-install the MSP430 Application UART software drivers if you move the USB connection to a different USB port on your PC.

Technical Support:

Please do not email us requests for technical support, use the link above and post your questions on the tech support forum.

Appendices

Appendix A: System Requirements:

- Texas Instruments MSP430 LaunchPad Evaluation Kit. This circuit board is the core of the ServoChron™.

- Power Source - Onl;y use a 3.7V to 6.0V battery. Confirm that it has sufficient current to power two servos.

- Servo Motors - We recommend a micro servo designed for use with a single LiPo cell. These servos are optimized for use with a 3.7V battery. Older servos designed for 5V systems may work but will require additional cells (more weight), and modified wiring.

- Trigger switch - This can be an off the shelf switch mounted to the rocket in such a way as to change state when the rocket leaves the ground, or something even simpler such as a bit of wire affixed to the ground that is loosely connected between the two connections for the trigger switch so that the connection is broken when the rocket lifts off and starts the timer.

| Qty | Part | Description | |

| 1 | MSP-EXP430G2 | MSP430 LaunchPad Value Line Development kit) | |

| 1 | R13-509A-05-BR | SWITCH, PUSHBUTTON, SPST, 3A, 250V | |

| 1 | N160.1S.25 | Turnigy nano-tech 160mah 1S 25~40C Lithium Polymer Cell | |

| 1 | HK9727 | Mini Plug Extension for Micro Battery 10cm | |

| 2 | HK9710 | JR-Type Servo Extension 10CM Servo Lead | |

| 2 | HXT900 | HXT900 9g / 1.6kg / .12sec Micro Servo | |

ServoChron, and the ServoChron Logos are ™ and © 2011-2017 U.S. Water Rockets All rights reserved. U.S. Water Rockets, and U.S. Water Rockets Logo are ™ and © U.S. Water Rockets All rights reserved.

Notice: The information contained in this project is provided "AS IS" without warranty, express or implied. U.S. Water Rockets makes no warranty as to the reliability, accuracy, timeliness, usefulness, adequacy, completeness or suitability of the information.

[Back to Table of Contents]

Servochron™ single/dual servo water rocket parachute deployment timer by

U.S. Water Rockets is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported License.

Servochron™ single/dual servo water rocket parachute deployment timer by

U.S. Water Rockets is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported License.