U.S. Water Rockets Universal Fin Can

Perfect fins for any water rocket bottle diameter.

For a while now, we have been experimenting with ways to make water rocket construction easier, faster, and more profesional looking. One area of the rocket which many people find

particularly time consuming and challenging is the fin section. In the past, we published our Removable Box Fin Tutorial,

which streamlines the fin construction process, making it much easier.

More recently, we have been trying to take fin construction to the next level, by using 3D printing technology. Our initial effort resulted in a set of fins which are joined together

by a cylindrical section that holds them in perfect alignment. This arrangment is commonly referred to as a "Fin Can". Our first designs date back several years, to when 3D printing

technology was in its infancy, and with the techniques and tools available at the time, we created an attractive and functional design, which was tricky to print, and was much

heavier than we would have preferred.

...

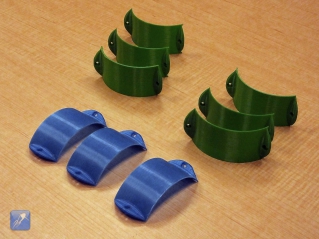

We then took a different approach to the deisgn, and came up with a set of 3D printed brackets, which would attach together using nylon screws, which would hold a set of flat fins

pre-cut from traditional fin materials. The Self-Aligning Fin Brackets performed very well, and we used them over a prolonged period of time for various rocket projects and test

launches. We were satisfied that the design was fully tested and released the 3D print files on our Thingiverse page [http://www.thingiverse.com/USWaterRockets].

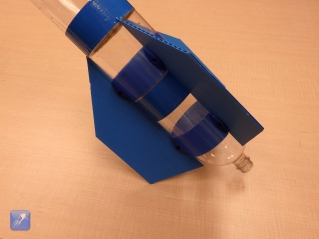

Only then did a flaw in the design appear. What we failed to consider in the design was that 2 liter bottles vary slightly in diameter in different parts of the world. Even the same

country can use multiple slightly different size bottles. For some people the fin brackets were too big and for others they were too small. There didn't seem to be an easy way to

compensate for the variations, so we withdrew the model and went back to the drawing board to come up with something much better. The Universal Fin Can.

For a while now, we have been experimenting with ways to make water rocket construction easier, faster, and more profesional looking. One area of the rocket which many people find

particularly time consuming and challenging is the fin section. In the past, we published our Removable Box Fin Tutorial,

which streamlines the fin construction process, making it much easier.

More recently, we have been trying to take fin construction to the next level, by using 3D printing technology. Our initial effort resulted in a set of fins which are joined together

by a cylindrical section that holds them in perfect alignment. This arrangment is commonly referred to as a "Fin Can". Our first designs date back several years, to when 3D printing

technology was in its infancy, and with the techniques and tools available at the time, we created an attractive and functional design, which was tricky to print, and was much

heavier than we would have preferred.

...

We then took a different approach to the deisgn, and came up with a set of 3D printed brackets, which would attach together using nylon screws, which would hold a set of flat fins

pre-cut from traditional fin materials. The Self-Aligning Fin Brackets performed very well, and we used them over a prolonged period of time for various rocket projects and test

launches. We were satisfied that the design was fully tested and released the 3D print files on our Thingiverse page [http://www.thingiverse.com/USWaterRockets].

Only then did a flaw in the design appear. What we failed to consider in the design was that 2 liter bottles vary slightly in diameter in different parts of the world. Even the same

country can use multiple slightly different size bottles. For some people the fin brackets were too big and for others they were too small. There didn't seem to be an easy way to

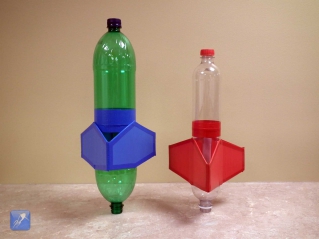

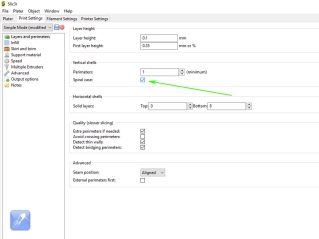

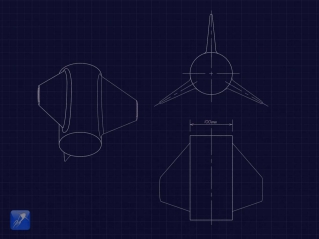

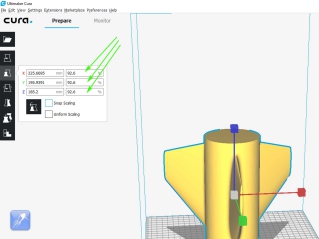

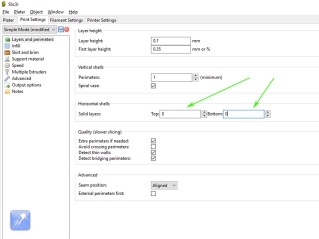

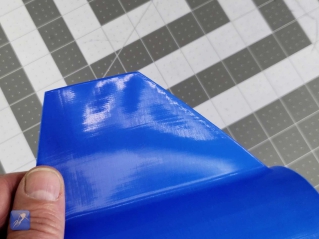

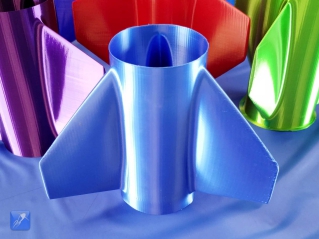

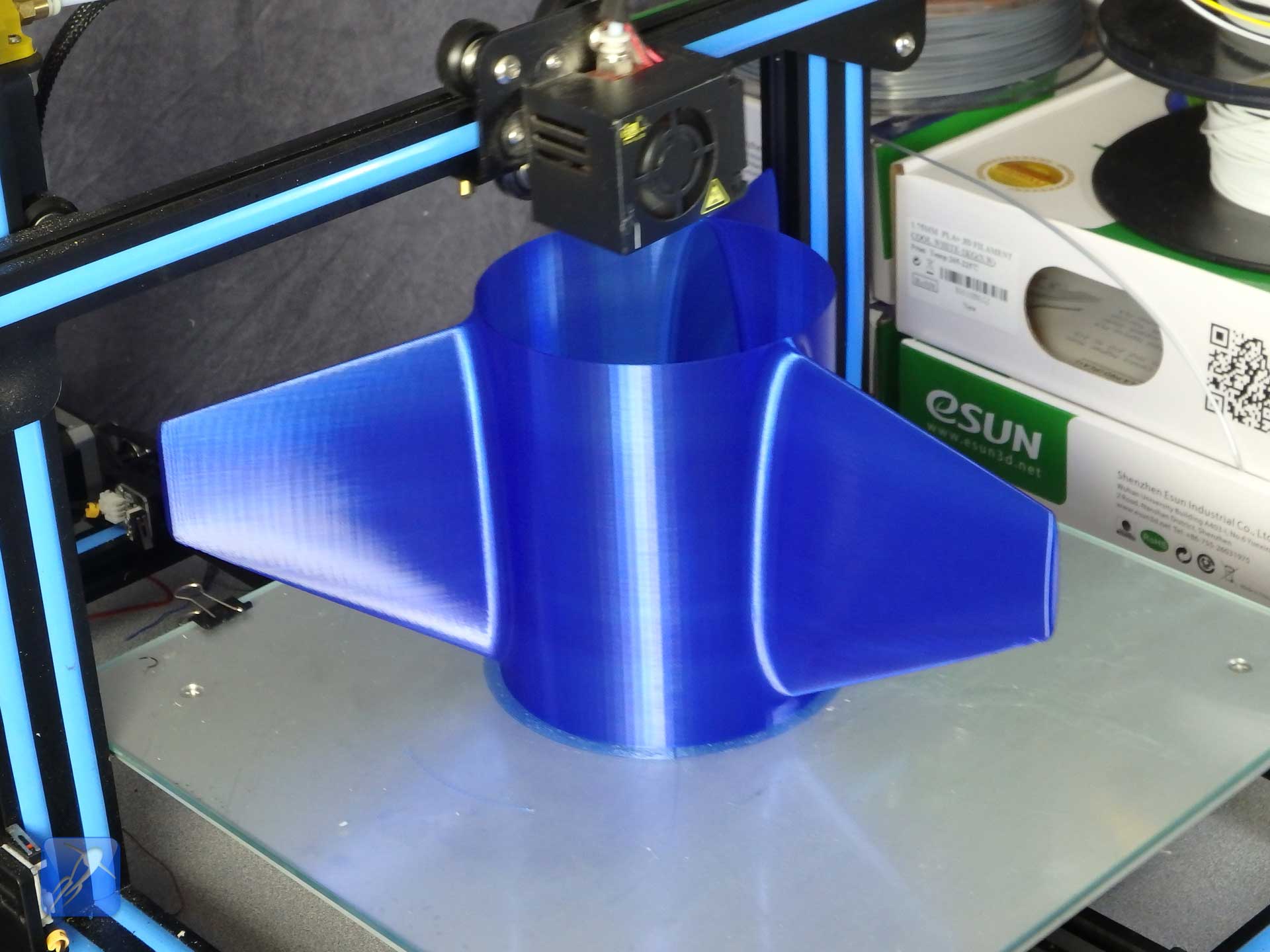

compensate for the variations, so we withdrew the model and went back to the drawing board to come up with something much better. The Universal Fin Can.The Universal Fin Can is superior to both of our previous attempts because it is both strong and lightweight, and looks amazing. The universal fin can is designed to take advantage of a seldom used setting in your 3D printer's slicer to generate a fin can that has the most desirable combination of properties. It's extremely rigid and also very lightweight. This design takes advantage of the principal of structural skin, where the tensile and compressive loads are completely supported by the skin of the structure, like an egg shell. The setting you need to use is called "Vase Mode" or "Spiralize Outer Contour" mode. Every popular slicing program has a mode similar to this, and it creates an object by extruding a continuous perimeter layer in a spiral pattern from bottom to top. This mode produces beautiful prints with single extrusion width walls very quickly, which is perfectly suited for this application. While the fins were stong and looked great, we still had to tackle the issue of fitting every bottle easily. We realized the answer was to scale our current design such that it fits a theoretical 100mm diameter bottle, and then every other bottle size becomes a simple percentage scale of that model. Any diameter bottle can easily be supported by simply using the "scale" feature of your slicing software to scale by the diameter in millimeters expressed as a percentage. For example, an 83.5mm diameter bottle would be 83.5% scaled. A 135.3mm diameter bottle uses scaling of 135.3% in the slicer, and so on. You can also experiment with setting the height scale to different values if you want to make the fin can longer or shorter. If you can measure the diameter of your bottle, you can make a Universal Fin can that fits! You can find a link to this model on our thingverse page [https://www.thingiverse.com/thing:3223207]. But before you print your own, there are a few printer settings you should be aware of. When you enable the "vase" mode in your slicer, you should disable printing the top and bottom of the print, otherwise your fin can will be capped off at the bottom, like a vase. If there's no setting to directly disable printing the top and bottom, you can set their thickness to 0 and they should not print. Another issue to look out for is warping on larger diameter fin cans. This is caused by the plastic shrinking as it cools and creating stresses in the print. Adjusting the temperature lower can help, and failing that a larger bore print nozzle size can eliminate this issue. It's also a good idea to print a small portion and then cancel the print, then test fit the resulting print before wasting time and plastic on a slightly incorrect scale. If the print is a touch small, then scale up a fraction of a mm and try again. Scale down if the print is too large. Eventually, you will find a print scale with a perfect fit for your bottle and you can go ahead and print the whole thing. Once your Universal Fin can is printed, you can slide it on your bottle and glue or tape it in place. After that, it’s ready for launching! 3D Printed Universal Fin Can Video Tutorial: